Yeast Specifications

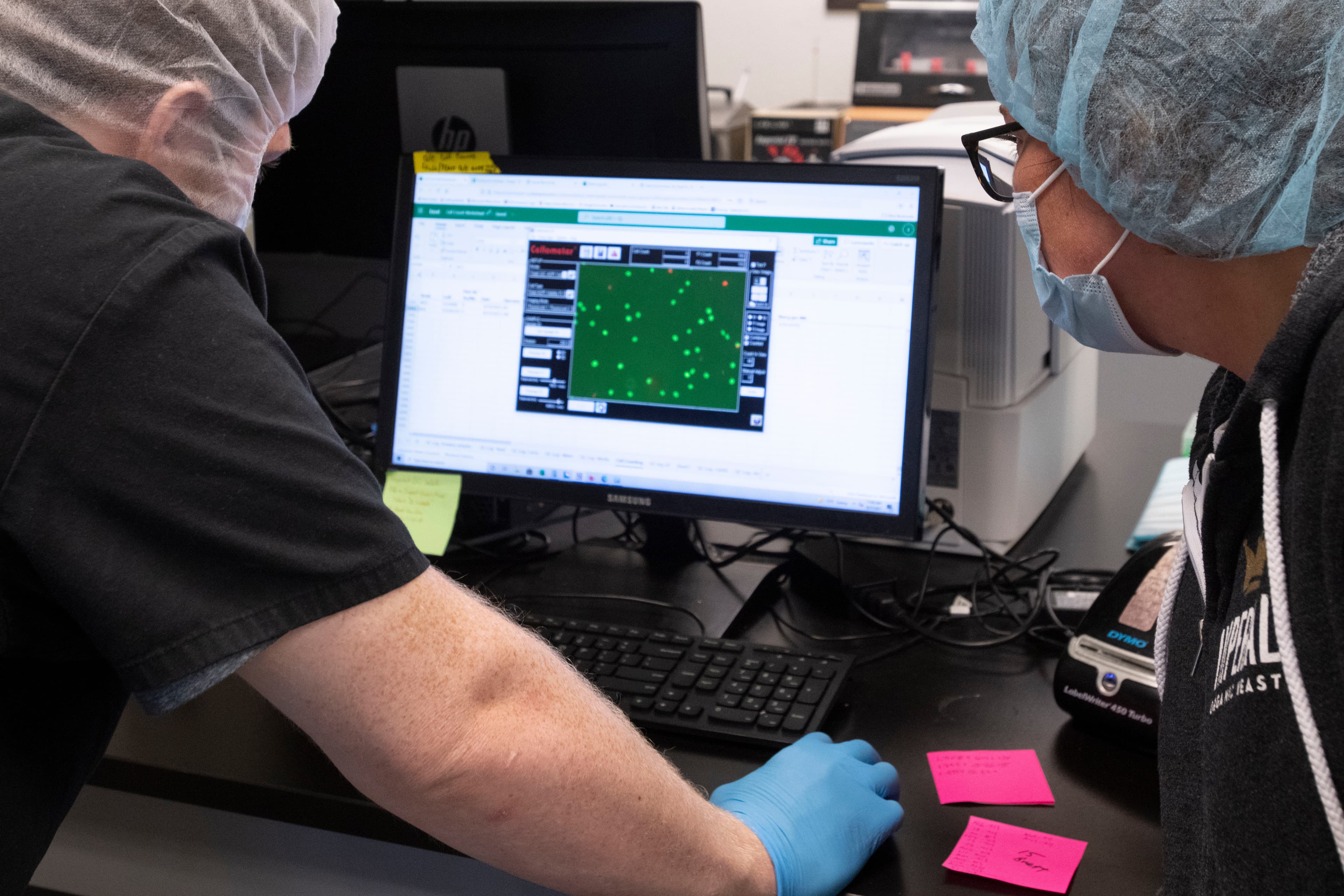

We pride ourselves on accurate and consistent package cell counts every pitch, every time!

You can find our product specification data sheets here.

Ale & Lager Culture Cell Counts

Imperial Yeast packages slurry with a specification of 1.29 x 1012 total viable cells per Verified Unit (VU). This is true for every pitch every time.

In an effort to save our customers shipping costs, Imperial Yeast customizes each pitch by concentrating slurries to deliver the same number of total cells (1.29 x 1012) in the least amount of liquid. Each order and amount of concentration is strain and batch dependent. Each unit of 1.29 x 1012 total cells is referred to as a “Verified Unit.” What that means is the yeast slurry volume/weight may change, but the total cell count will always be what you ordered.

Pitch Rates

As brewers, it is important to decide which pitch rates perform best for our brewery and how to consistently quantify them from batch to batch. Imperial Yeast offers many tools, including our brewing calculators, to help you decide what is best for you and how to optimize pitch rates for your yeast management program.

In short, pitch rates matter. They are a major driving force in the consistency and quality of your beer. They play an important role in the health and growth of yeast cells, fermentation kinetics, and flavor and aroma outcomes. Pitching too little yeast can increase esters and higher alcohols, and lead to longer or stalled fermentations, incomplete attenuation, extended VDK (diacetyl) reduction times, and/or potential over carbonation in packaged beers. Pitching too much yeast can reduce esters and promote sulfur compounds. It can also decrease cell growth, resulting in a final population of yeast with a higher percentage of older and potentially unhealthy cells. Over time, this may contribute to sluggish fermentations, extended VDK (diacetyl) reduction times, shifts in pH, and changes to beer profile.

So, what pitch rates do we recommend? Pitch rates are often denoted as yeast cells per milliliter (cells/mL), or as yeast cells per milliliter per degrees Plato (cells/mL/ºP). At Imperial yeast, we measure our pitch sizes by the latter. Using cells/mL/ºP allows us to take into account the amount of sugar we want each yeast cell to consume during fermentation in order to reach full attenuation. Another way to think about it is, “how much “work” must each yeast cell perform to get the job done well?

Most brewing publications and generally accepted brewing industry practices recommend a pitch rate of 0.75 million cells/mL/ºP for ales (>60ºF+) and 1.0 million cells/mL/ºP for lagers (<60ºF). At Imperial Yeast, we figured that if that's the standard recommendation, then our pitchable quantities should get you within that ballpark. To achieve this, we averaged all of the original gravities found in the BJCP guidelines, which came out to be 14ºP (1.057SG). Our slurry density is always 1.29 trillion healthy viable cells per Verified Unit. Pitching at 1EqL/bbl, results in a pitch rate of 11 million cells/ml. When we divide 11 by 14ºP we get 0.78, which is the standard pitch rate for an ale when rounded to 0.75 million cells/mL/P.

Of course not all beers and gravities are the same. To simplify things, we’ve provided a reference chart indicating our standard pitch rate recommendations and have developed an easy to use online pitch rate calculator to help you decide which pitch size is best for your next brew.

Oxygenation

In addition to pitch rates and temperature, oxygen has a major effect on the growth and health of yeast cells during fermentation. Oxygen is required for yeast membrane unsaturated fatty acid (UFA) and sterol synthesis which maintain cell flexibility and permeability, and is critical for cellular transport of energy sources and nutrients. UFA and sterol content is also the primary factor limiting cell growth. With each cell doubling, UFA and sterol content is diluted until it reaches a critical point where the cells can no longer divide. Without proper oxygenation and subsequent UFA/Sterol synthesis, less growth occurs reducing the amount of yeast available to do the work. This can result in impacts on beer flavor and aroma, extended VDK (diacetyl) reduction times, long fermentation times, stalled or incomplete attenuation, long tank residency, and potential over carbonation in packaged beer.

To ensure adequate oxygenation, we recommend adding pure oxygen inline through a sintered stainless steel stone during knockout using an Oxygen Flow Meter measuring in liters per minute (LPM). There should be at least 10 ft. of hose between the oxygen stone and the receiving tank to limit oxygen breakout. This method allows the brewer to achieve accurate and consistent dissolved oxygen (DO) levels with the delivery of a set amount of oxygen to a specific volume of wort.

By generally accepted brewing industry standards, it is best practice to verify DO levels by using a DO meter like this Portable Dissolved Oxygen Meter to ensure proper oxygenation. A helpful tool for estimating oxygen flow rates is available online using Imperial Yeast’s DO Calculator. The recommended levels of dissolved oxygen may vary, but in general, lager strains require ~8-12 ppm, ale strains require ~12-14 ppm, and high-need strains like A38 Juice, require 20-25 ppm. Highly flocculant strains and/or low pitch rates may also benefit from higher levels of dissolved oxygen.

Temperature

Understanding the role that temperature plays in yeast health and fermentation is critical, if we want to create quality beer consistently and maintain happy healthy yeast.

In addition to pitch rates and oxygen, temperature has a major effect on the growth and health of yeast during fermentation. As a result, fermentation kinetics and the final character of the beer are greatly impacted. Warmer or cooler temperatures during fermentation can increase or decrease yeast’s growth and their rate of growth, the rate of fermentation, the levels of ester and alcohol expression, and influence a plethora of other fermentation by-products.

In extreme cases, yeast that become too cold may struggle to grow during the lag and log phases and/or flocculate prematurely, resulting in less new healthy yeast cells and poor harvests. Slow, or inhibited growth may also result in sluggish or stalled fermentation, increased VDK (diacetyl) reduction times, and often less ester and alcohol expression. Yeast that become too hot can experience rapid growth, high levels of stress, and potentially lower viabilities. Higher temperatures often result in rapid fermentation and VDK reduction times, as well as higher alcohols and esters.

In order to maintain healthy yeast cell growth and healthy fermentation, temperature, along with pitch rates and oxygen must be in balance.

For more questions regarding pitch rates and other yeast management topics, please see our technical support, or contact techsupport@imperialyeast.com for assistance. Cheers!

.jpg&w=3840&q=75)